●Can accommodate thicknesses of 0.03 to 1.0 mm.

●In addition to high-precision cutting, simple welding is also possible by adjusting the laser output.

The latest positioning and processing technology enables processing of a minimum laser input diameter of 18μm and exit diameter of 10μm on a 30μm thick stainless steel sheet required for small-scale applications.

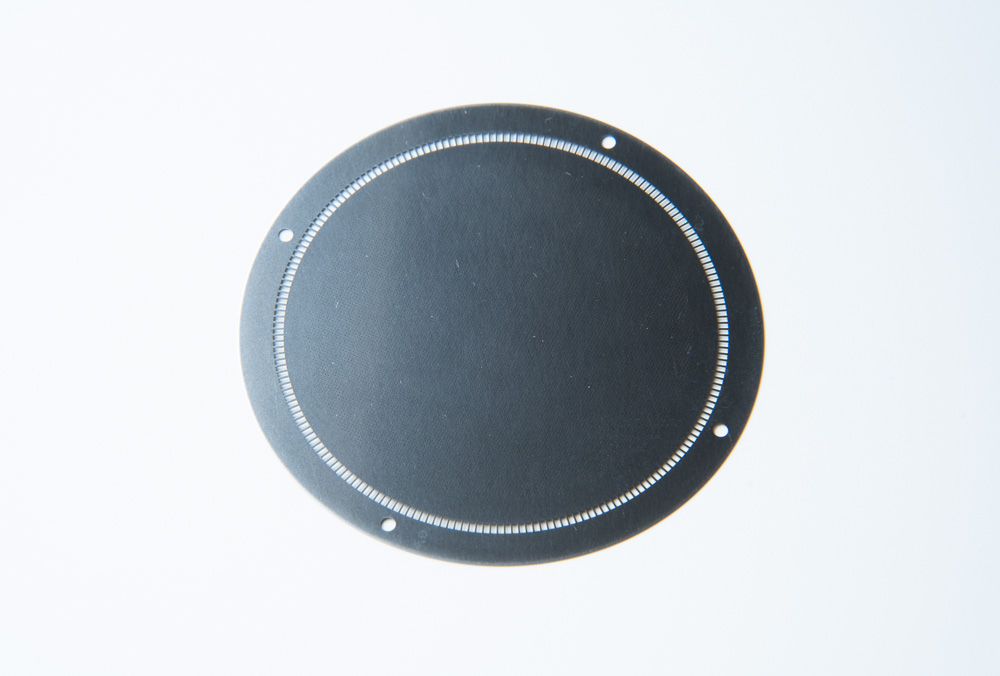

encoder disc

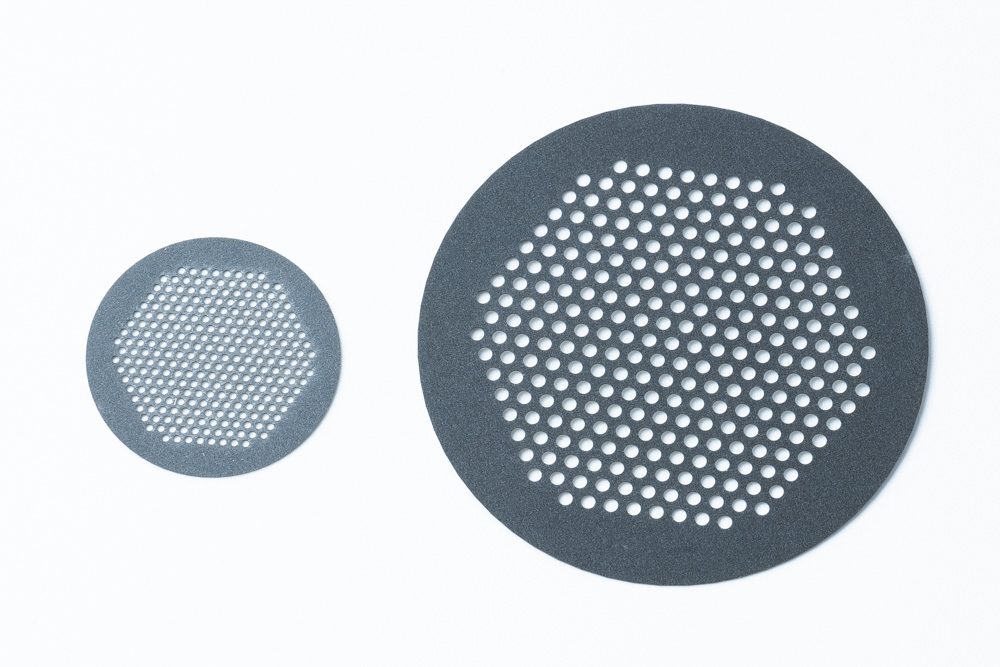

filter

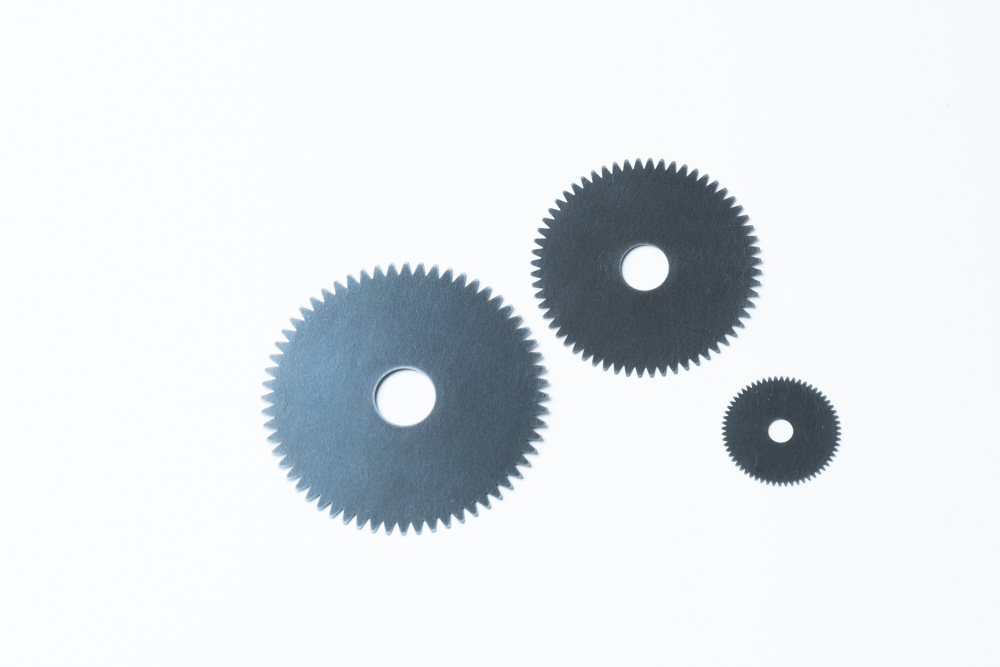

gear

optical pin pole

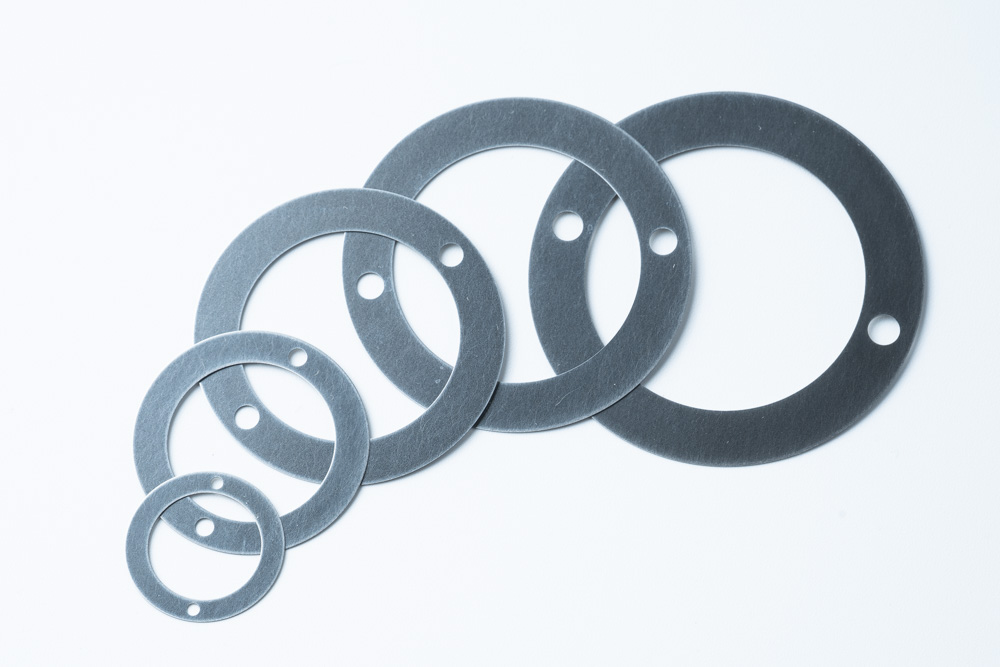

shim plate

vapor deposition mask

■Penetration check function

Normally, the processing status is checked visually or with an inspection machine after processing, but the laser processing machine used for processing this product is equipped with a penetration check function (RTPC), so it is possible to check the processing status while processing. is possible.

■CMM

You can also compare the processing measurement results using a coordinate measuring machine with CAD data.

It can also be used to measure the three-dimensional dimensions of existing parts, and use this data for mass production and prototype development.