HOME > Product Overview > Metalmask

Stencils are jigs used to print solder cream onto circuit boards.

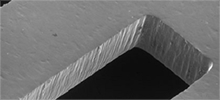

It is designed to manually print solder onto the circuit through the hole opened on the stainless steel.

We use Laser Cutting, Chemical Etching and Additive Manufacturing.Following the development of machines, we too are required for higher quality stencils.

At Nakayama Riken, we make the best highly precision and functional stencils by carefully discussing with our clients

We use high quality YAG laser. It allows clear cutting and is possible to use with any material. List of Product

Using high exposure and developed chemical etching, it is possible to open multiple holes at once and available to manufacture any type and size of stencils.Using high exposure and developed chemical etching, it is possible to open multiple holes at once and available to manufacture any type and size of stencils. Characteristic list

The opening is made with electroforming made by nickel.It is applicable for fine openings and multiple thickness. List

Smoothing out the edges of the SUS plate after cutting out the holes will smoothing the solder printing. Thus ease mounting parts on QFP/BGA the size below 0.4mm or on 0603 chip. More details

By usung a special method to coat both sides of SUS plate(backing), it will improve the soldier printing quality and reduplication of printing.

By combining with electropolishing it could be applied on 0402 chips.

More details

Half etching could make different thickness of holes to control the amount of soldier past on a certain part. Furthermore, if parts are loaded on the circuit, by half eching the back of the stencil it could avoid the parts and improve the printing quality. However, there are limits of usage so please contact us for more details.

| Lable Sign | Manufacturing Type | Price | Printing Quality | Continues Printing | 0.4 pitch QFP QFP | 0402 Chip | Quality | Features |

|---|---|---|---|---|---|---|---|---|

| L | Laser Cutting | ◎ | ○ | ○ | △ | × | ◎ | High quality cutting, applicable on any stencil.Well balanced QCD. |

| KF-L | Laser Cutting + Elecrtropolishing | ○ | ◎ | ○ | ○ | △ | ◎ | Minimum distortions to effect printing quality |

| FC-L | Laser Cutting + Thin Fluorine Coating | ○ | ○ | ◎ | ○ | △ | ◎ | Water-repellent applied on the back and inner side of laser cutted stencil. |

| FC-K-L | Laser Cutting + Thin Fluorine Coating + Electropolishing | △ | ◎ | ◎ | ◎ | ◎ | ◎ | The highest specification we can offer with all of the best qualities. |

| TF-L | Laser Cutting + Thick Fluorine Coating | ○ | ○ | ◎ | △ | × | ○ | High Water-repellent applied on the back and inner side of laser cutted stencil . |

| TF-K-L | Laser Cutting + Thick Fluorine Coating + Electropolishing | △ | ◎ | ◎ | ○ | × | ○ | Minimum distortions and high water-repellent on the back and inner side. |

| E | Chemical Eching | ◎ | △ | × | × | × | △ | One cutting process, thus number of cutting does not affect the price. |

| KF-E | Chemical Etching + Electropolishing | ○ | ○ | ○ | △ | △ | △ | Minimize the distortion to lessen the effect of printing quality. |

| FC-E | Chemical Etching + Thick Fluorine Coating | ○ | △ | ◎ | △ | △ | △ | Water-repellent applied on the back and inner side of chemical eched stencil. |

| FC-K-E | Chemical Etching + Thick Fluorine Coating + Electropolishing | △ | ○ | ◎ | ○ | ○ | △ | Best for multiple cutting and clean printing. ex) printing flux. |

| TF-E | Chemical Eching + Thic Fluorin Coating | ○ | △ | ◎ | △ | × | △ | High Water-repellent applied on the back and inner side of chemical etched stencil. |

| TF-K-E | Chemical Etching + Thick Fluorine Coating + Electropolishing | △ | ○ | ◎ | ○ | × | △ | Best for multiple cutting and clean printing. ex) printing glue |

| A | Additive | △ | ○ | ○ | ○ | ○ | ○ | Applicable on wide range of thickness, good printing quality. |

| FC-A | Additive + Thin Fluorine Coating | × | ◎ | ◎ | ◎ | ◎ | ○ | Water-repellent applied on the back and inner side of electroformed stencil. |

| TF-A | Additive + Thick Fluorine Coating | × | ◎ | ◎ | ○ | × | △ | High Water-repellent applied on the back and inner side of electroformed stencil. |